无论是首次打出安瓶概念的MartiDerm玻璃安瓶精华液,还是引爆互联网的润百颜玻尿酸精华,他们都是把次抛化妆品推向大众的先行者。次抛化妆品不仅更新了消费者对化妆品的选购标准,也带来了全新的使用体验,增添了护肤的仪式感。

作为一种小众的化妆品,次抛化妆品突然爆红并非一日之功,而是靠多年的积累和沉淀,既有品牌对市场孜孜以求的挖掘,也有供应链在背后齐心协力的支持。那么,次抛化妆品究竟是如何炼成的呢?从原料到加工,从加工到成品,它都经历了哪些故事呢?

作为全国规模最大最专业的创意型化妆品次抛灌装代工厂,我们在韵斐诗这里找到了一份参考答案。

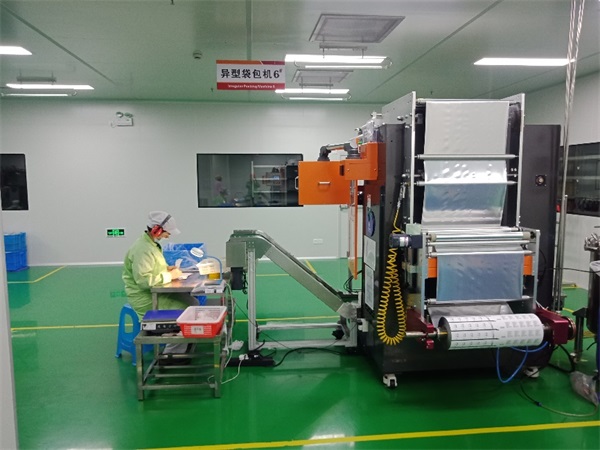

韵斐诗位于上海奉贤东方美谷园区庄行园区,占地面积约15亩,是一家有着14年次抛从业经历的ODM工厂,专注于化妆品次抛灌装,同时也溯源至次抛设备和次抛材料的合作研发。韵斐诗的产品线丰富且超前,有注塑面膜杯,泡罩,铝箔袋包,条包,立体铝箔AFP,软胶囊,安瓶等等,几乎涵盖了市面上所有的次抛类型,像一座次抛博物馆。

对次抛化妆品感兴趣的小伙伴,一定很好奇,次抛化妆品究竟是如何开发出来的呢?在韵斐诗大致可以分两种模式:

首先,品牌开发者先提出自己的产品创意,连同配方设计,包装建议在内。这种情况下叫做次抛产品ODM开发,两个月为一个周期。小小的次抛化妆品在这60天内从无到有,先经历配方打样选定,包材打样测试选定,接着又被送去第三方实验室做各种功效检测,还有必不可少的产品备案。随后就到了物料批量采购这一环节,这时候,成品大货生产出货就指日可待了,因为主要功夫都已经在前期做足了。

其次是品牌开发者直接提供内容物料体的OEM灌装模式,工厂会首先对料体的物理化学性质做一个科学的评估,并结合品牌开发者的意愿,推荐合适的次抛包装形式,一个半月就能完成出货。

通常,品牌开发者与工厂建立了默契的合作关系后,也就是产品返单,从返单订单下单,物料采购,成品大货生产出货,周期一般在1个月以内。

产品开发效率的提速也让我们看到韵斐诗次抛代工的灵活性。在韵斐诗一方看来,行业供应链一体化是大势所趋,作为代工企业仅仅做好自己本环节的工作是远远不够的,所以它努力打通上下游的节点,争取提供全方位的服务,为品牌开发者扫清更多的障碍。